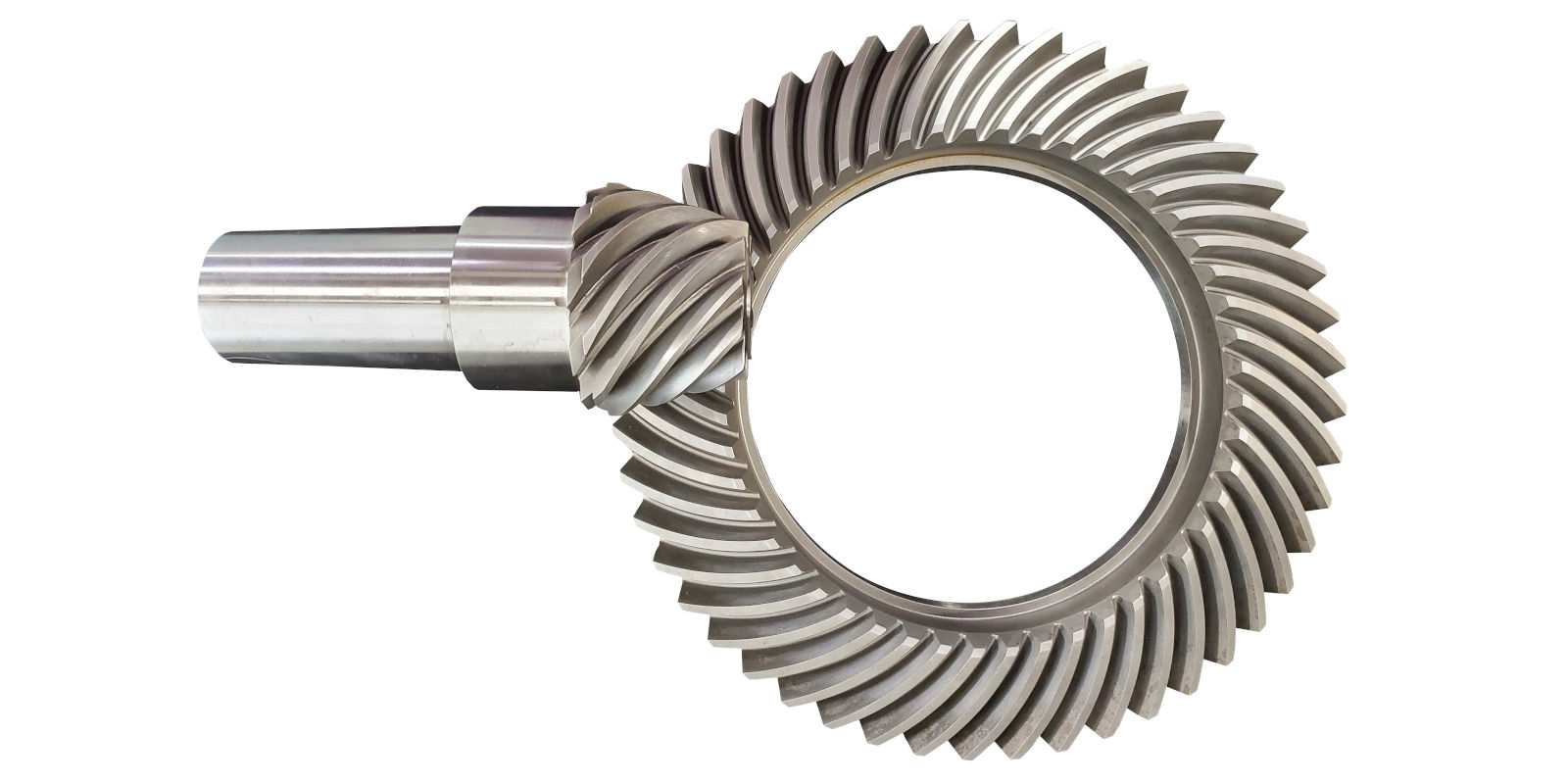

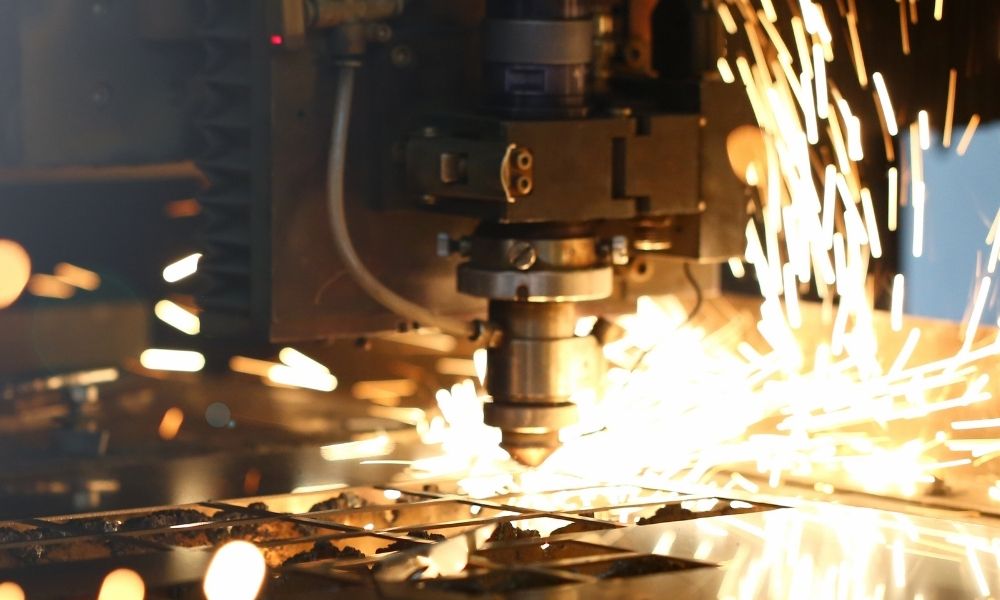

Whether your designing new gears for business equipment or reverse-engineering older gears, gear manufacturing can be a complicated process. In fact, most businesses often spend more time and money on gear designs and repairs than they anticipate. In this blog, we'll discuss how to avoid these costs and share the benefits of working with a custom gear manufacturer.

Customized Engineering

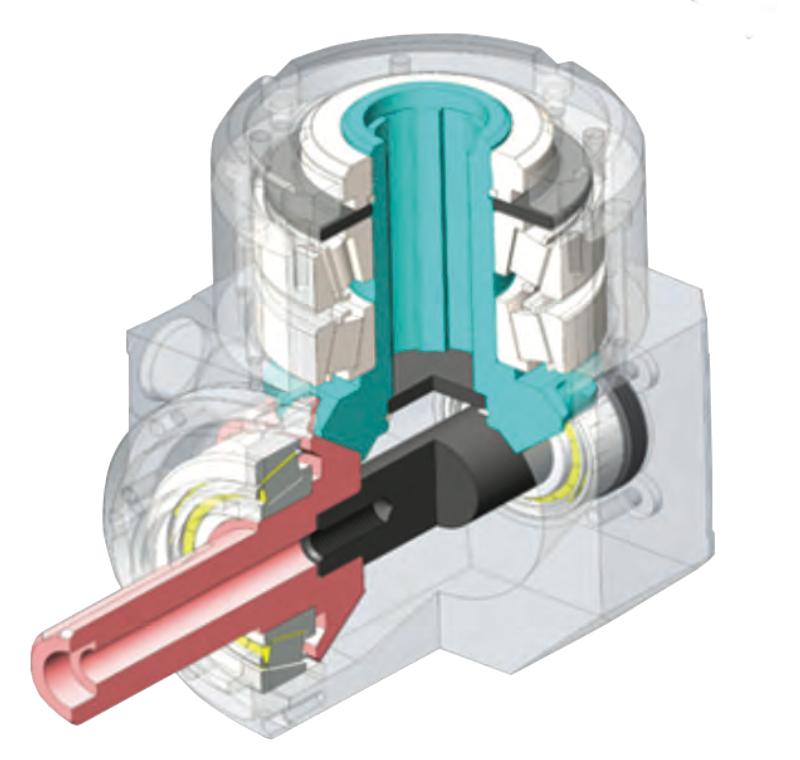

When you work with a custom gear manufacturer, you have access to a team of talented technicians and engineers skilled in constructing custom machinery. Regardless of whether you are developing gear designs or need guidance on larger machinery and equipment, gear manufacturers can meet the specific needs of your business.

With this customization also comes flexibility. Custom gear manufacturers will work with companies' schedules and provide access to different gears and parts. Instead of searching for additional gears and equipment, custom gear manufacturers are prepared with any mechanical tools necessary to complete your gear's design process.

Expert Guidance

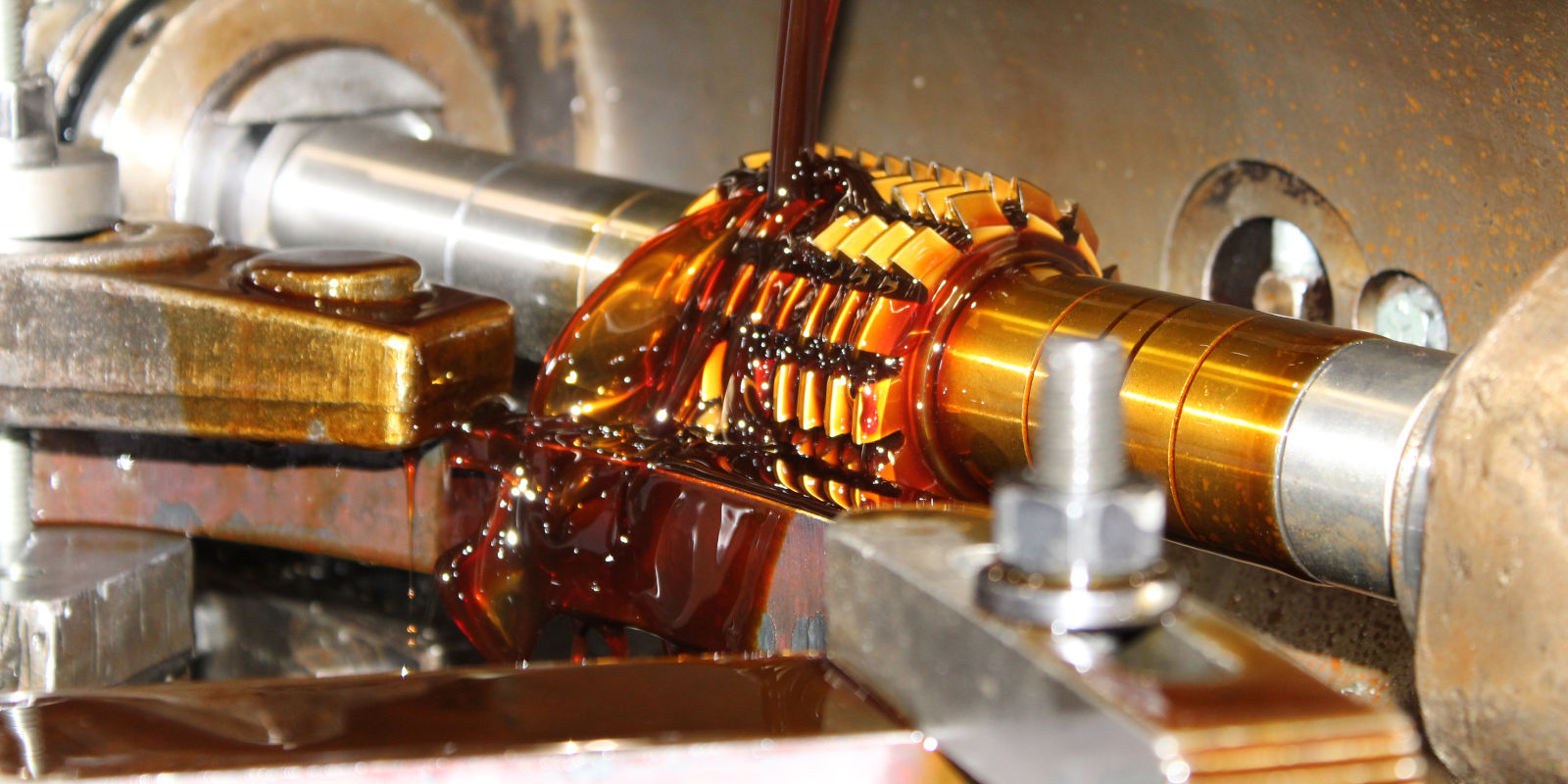

One of the best benefits of working with a custom gear manufacturer is having access to the knowledge and expertise of top mechanical engineers. Understanding gears may sometimes seem like learning a different language, especially when you try to research or understand the mechanical failures in your equipment. Working with custom gear manufacturers eliminates the stress of deciphering complex equipment and puts it in the hands of industry experts. Talented technicians will inspect your equipment, identify gear problems, update machinery, and provide detailed plans for avoiding future gear issues. This vast expanse of industry knowledge will maintain the longevity of equipment and proactively design improved gears and machinery for businesses.

Long-Term Savings

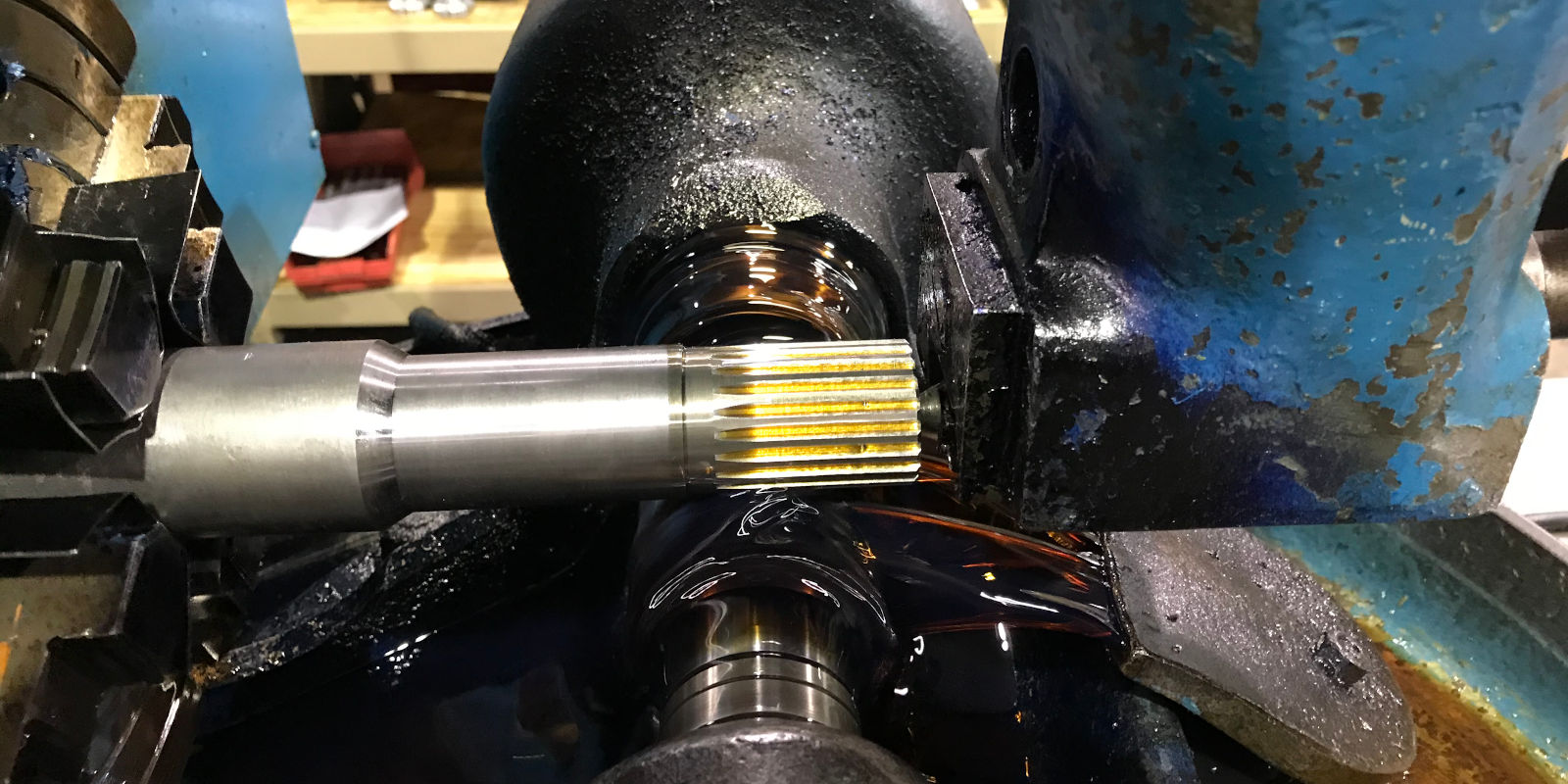

Working with a custom gear manufacturer saves more than money. Companies often waste time, stress, and attention in the process of problem-solving complicated gear equipment issues. Guessing what gears need repairs or how to improve the design of custom transmission pieces can easily cut into businesses' costs and prolong equipment failure.

When you work with customized engineers that craft and study your equipment to guarantee more efficient and effective machinery, these expenses decrease significantly. Custom gear manufacturing is an investment that saves time and money for your business gear services.

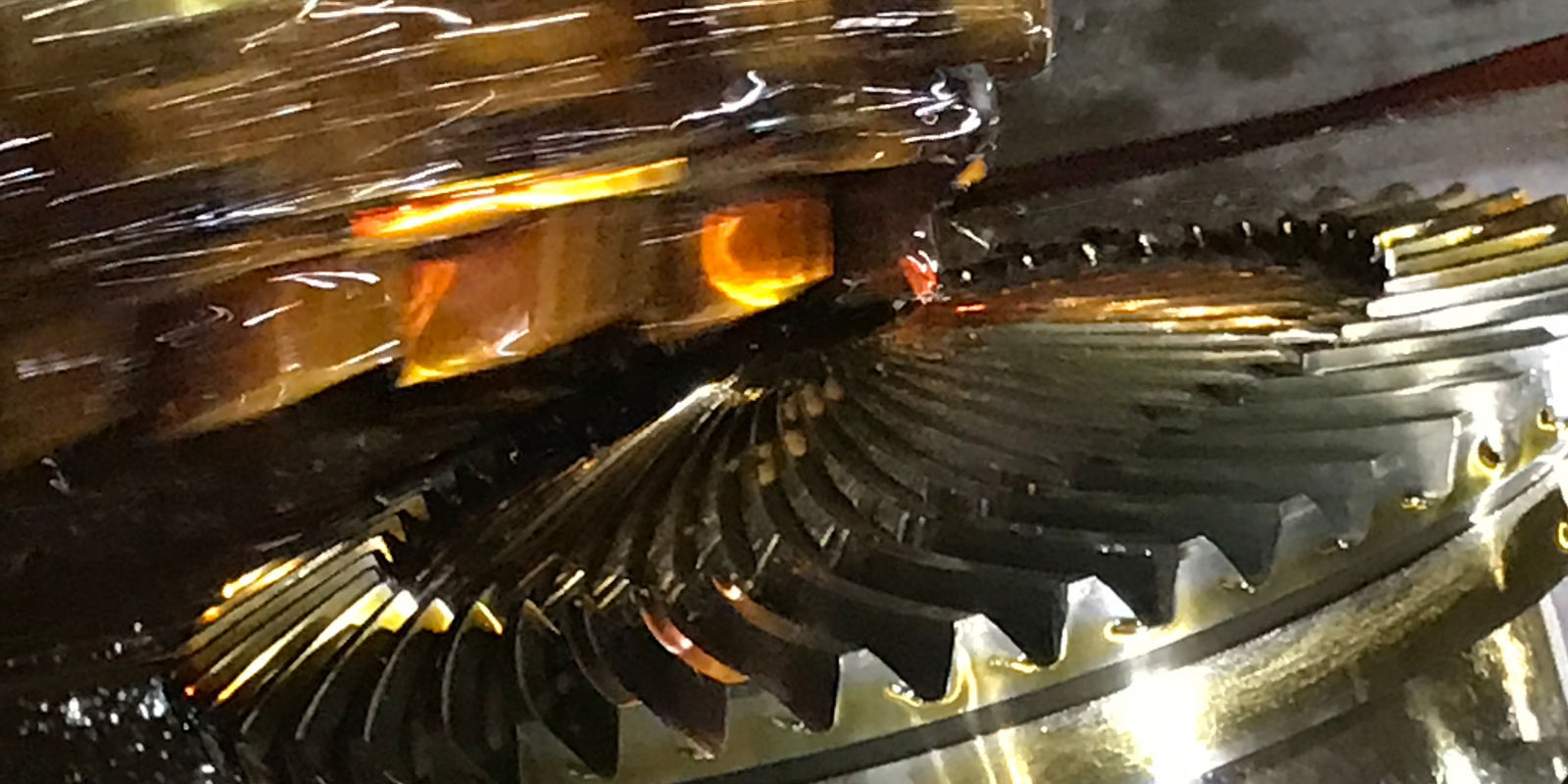

Don't let complicated or confusing gears and designs waste your business’s precious time, money, and energy. Custom gear manufacturers are trained to meet the needs of your company's equipment and ensure it has the highest quality design.

Here at Hy-Tech’s Power Transmission Group, we offer custom gear manufacturing to help minimize production costs and supply the best in gear services.

For all other inquiries...

For all other inquiries...