When understanding the measurements of different types of spur gears, specific terminology can seem vaguely similar and hard to understand. Circular pitch and diametrical pitch are two gear terms that are often mixed because of their similarities.

However, these measurements have plenty of differences that are essential to note. To learn more about circular pitch vs. diametrical pitch and their differences, continue reading below.

Circular Pitch

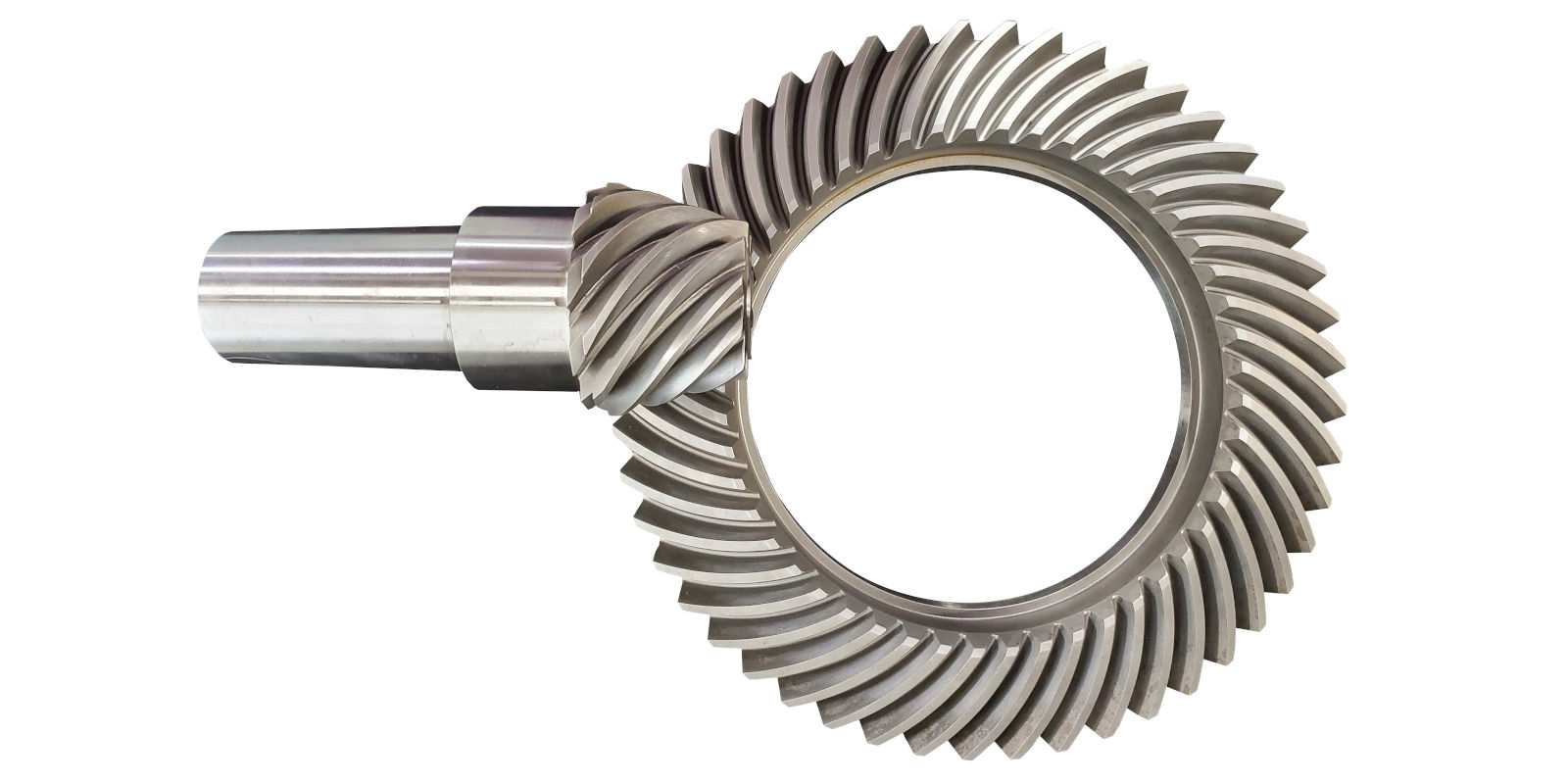

According to Keith Mobley's Plant Engineer's Handbook, the circular pitch of gears relates to the distance from one point of a gear tooth to another tooth point measured along the pitch circle. The pitch circle is an imagined circle that rotates in similar motions and circular rates as gear teeth. Circular pitch essentially measures the space between different spot points in gear teeth.

To find the circular pitch of gear, divide the circumference of the pitch circle by the number of gear teeth in a single gear. Circular pitches are not as common as diametrical pitch specifications. Circular pitch is mainly used for larger diameter gears.

Diametrical Pitch

Mobley also states that the diametrical pitch of gears relates to the ratio of gear teeth and pitch diameter. Pitch diameter is the measured diameter of a pitch circle. Essentially, the diametrical pitch of a gear is the number of gear teeth for each inch of pitch diameter.

In order to calculate the diametrical pitch, you must divide the number of teeth in a single gear by its pitch diameter. Manufacturers can also calculate the diametrical pitch by dividing pi by the circular pitch. While the circular pitch is mainly used for larger diameter gears, the diametrical pitch is more common for most gear specifications.

While these two pitch measurements may seem similar based on their calculations, they relate to two different measurements. Circular pitch focuses on calculating the distance between two points of gear teeth along the pitch circle line. In contrast, diametrical pitch relates to the ratio of gear teeth and pitch diameter.

Review the differences between circular pitch vs. diametrical pitch to separate these two pitch measurements and understand how they relate to spur gears and manufacturing.

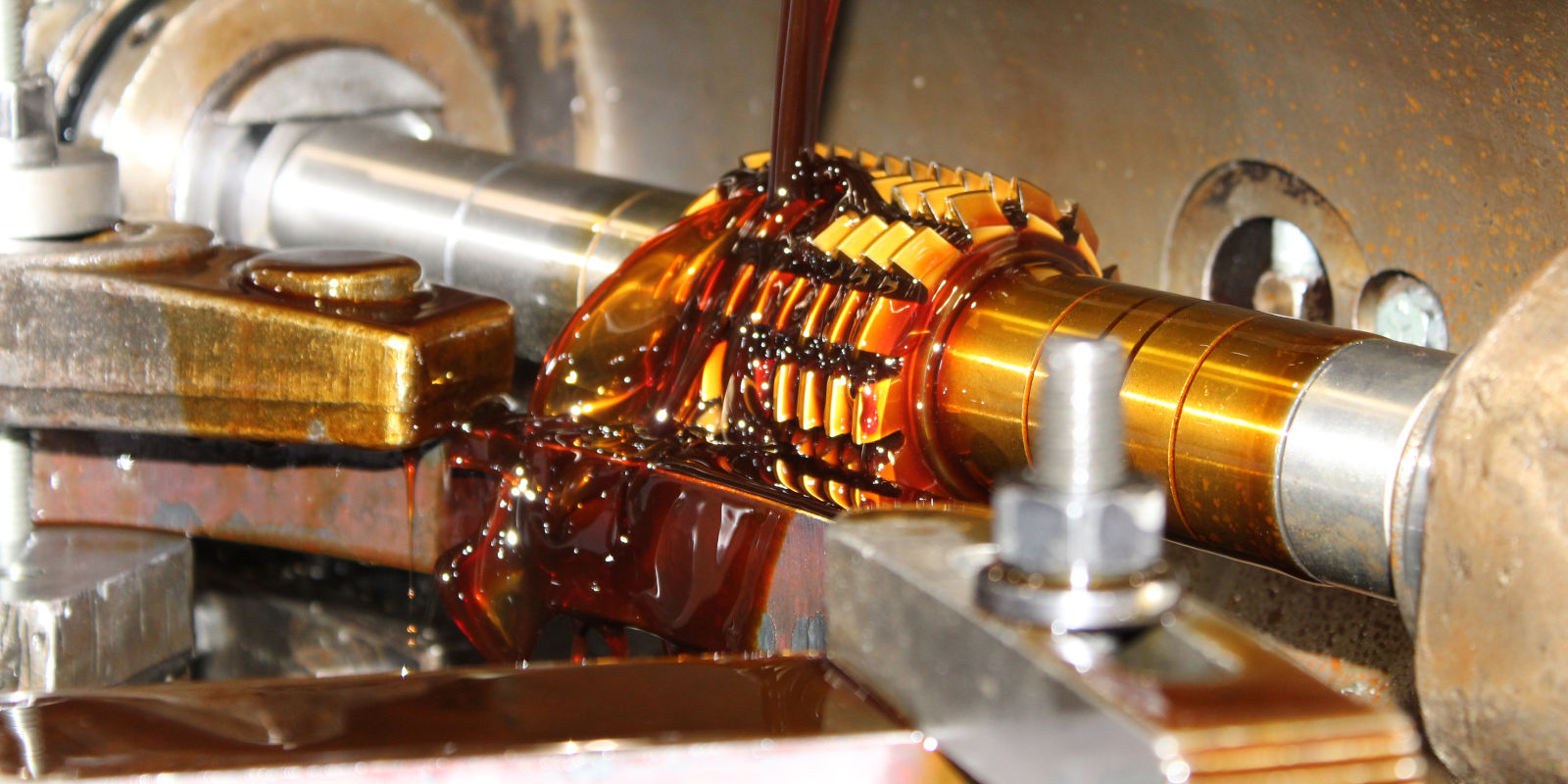

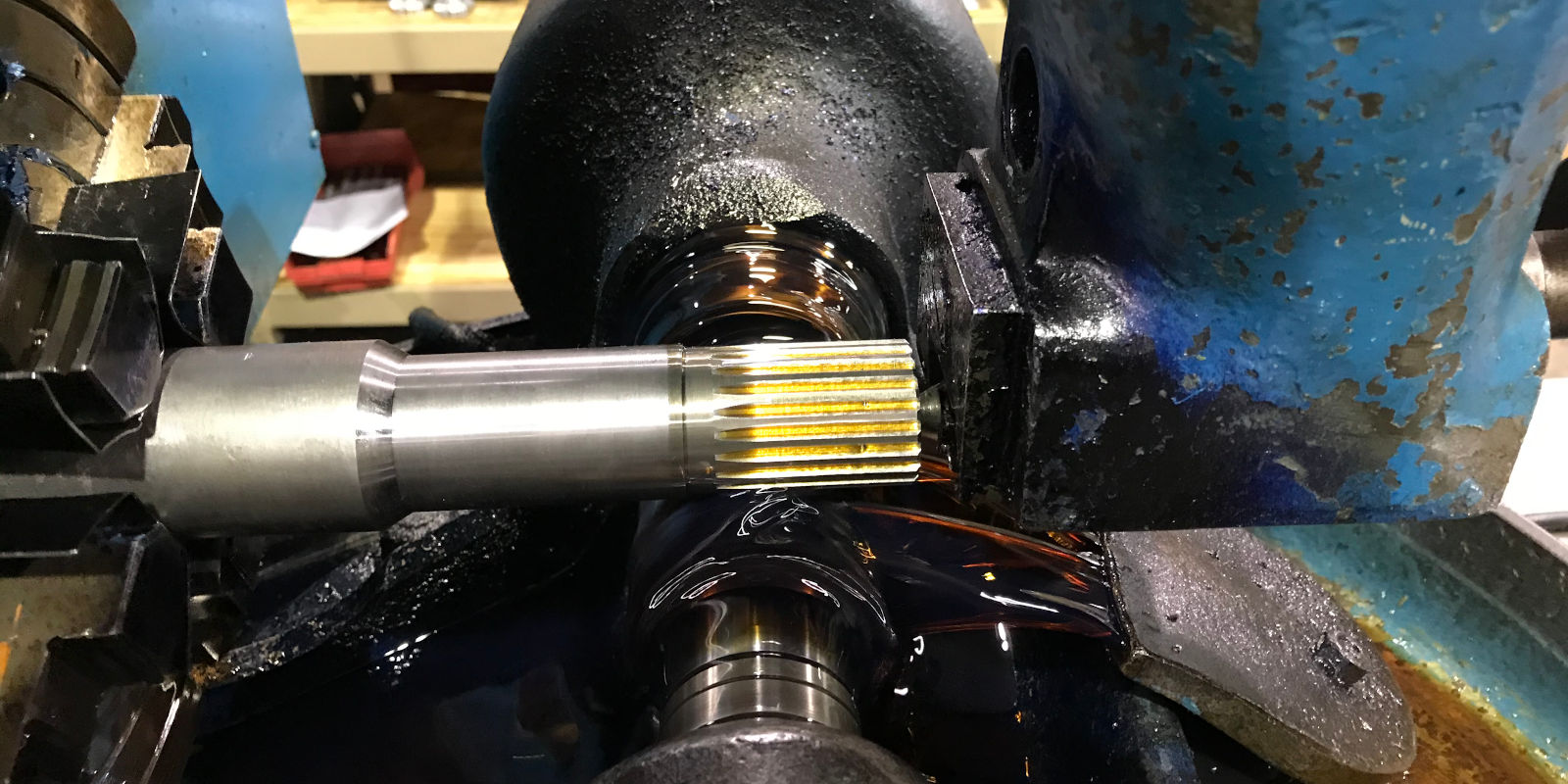

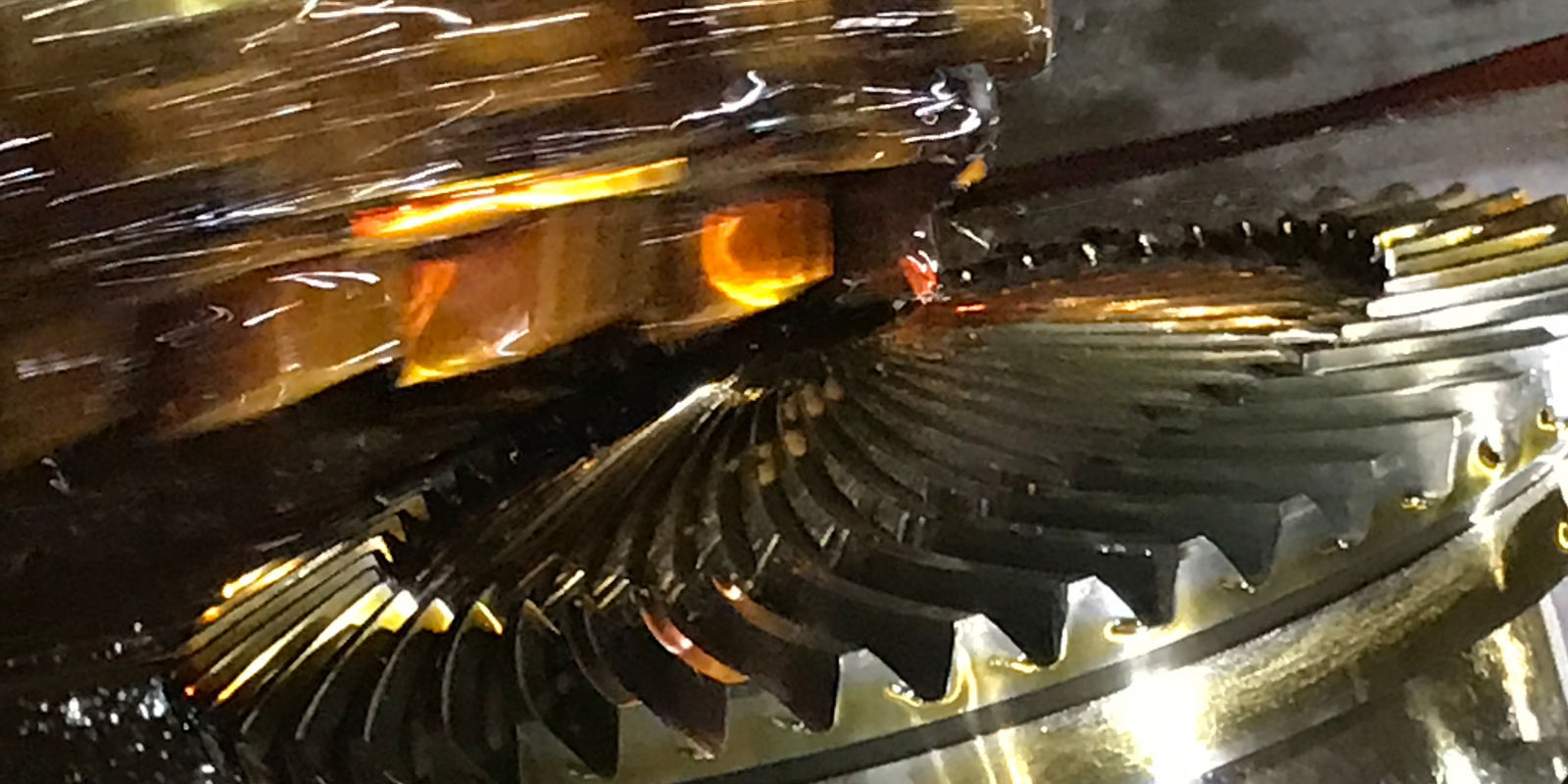

Here at Hy Tech's Power Transmission Group, we specialize in custom gear manufacturing and gearbox repairs to answer questions about your gear concerns. If your facility needs internal spline manufacturing, custom-made gears, or other mechanical services, check out our website for more information.

For all other inquiries...

For all other inquiries...