When you're new to the world of gears, it can be overwhelming to try to understand all the different types of gears and their applications. Although it may help to read through how gears operate in engineering processes, it can still be headache-inducing to try to understand these mechanisms. To learn more about the science behind gears and how they work, continue reading our blog below.

What Are Gears?

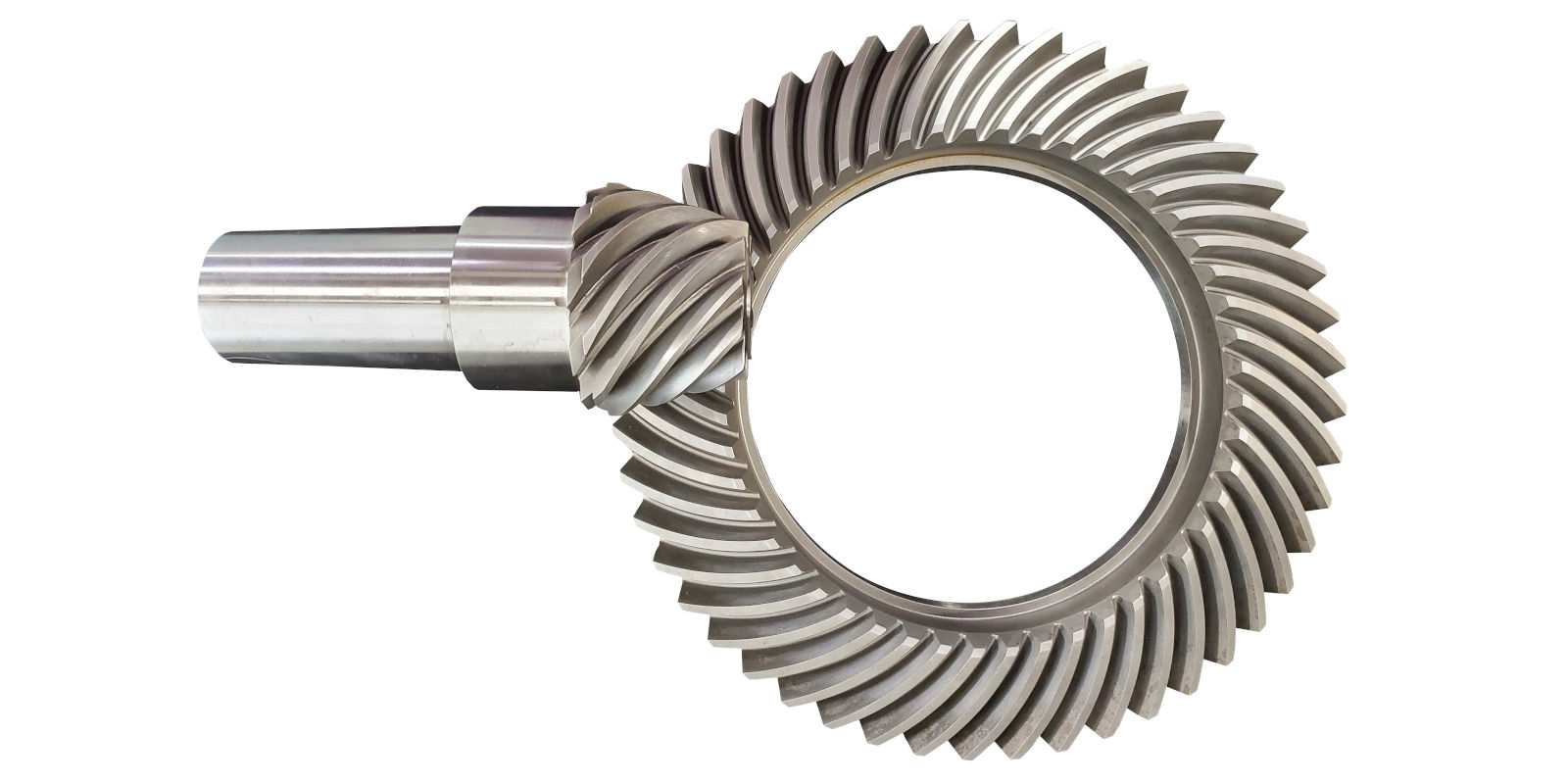

Gears are wheels inside machinery that use their cut edges, also known as gear teeth, to transmit power from one gear to another.

When one gear's teeth intersect with another gear's teeth, the two gears rotate and twist along their axis. These rotations are how gears can transmit power from one gear to another and operate inside machinery. Now that we understand their design let's examine what gears do inside machinery.

They Increase Speed

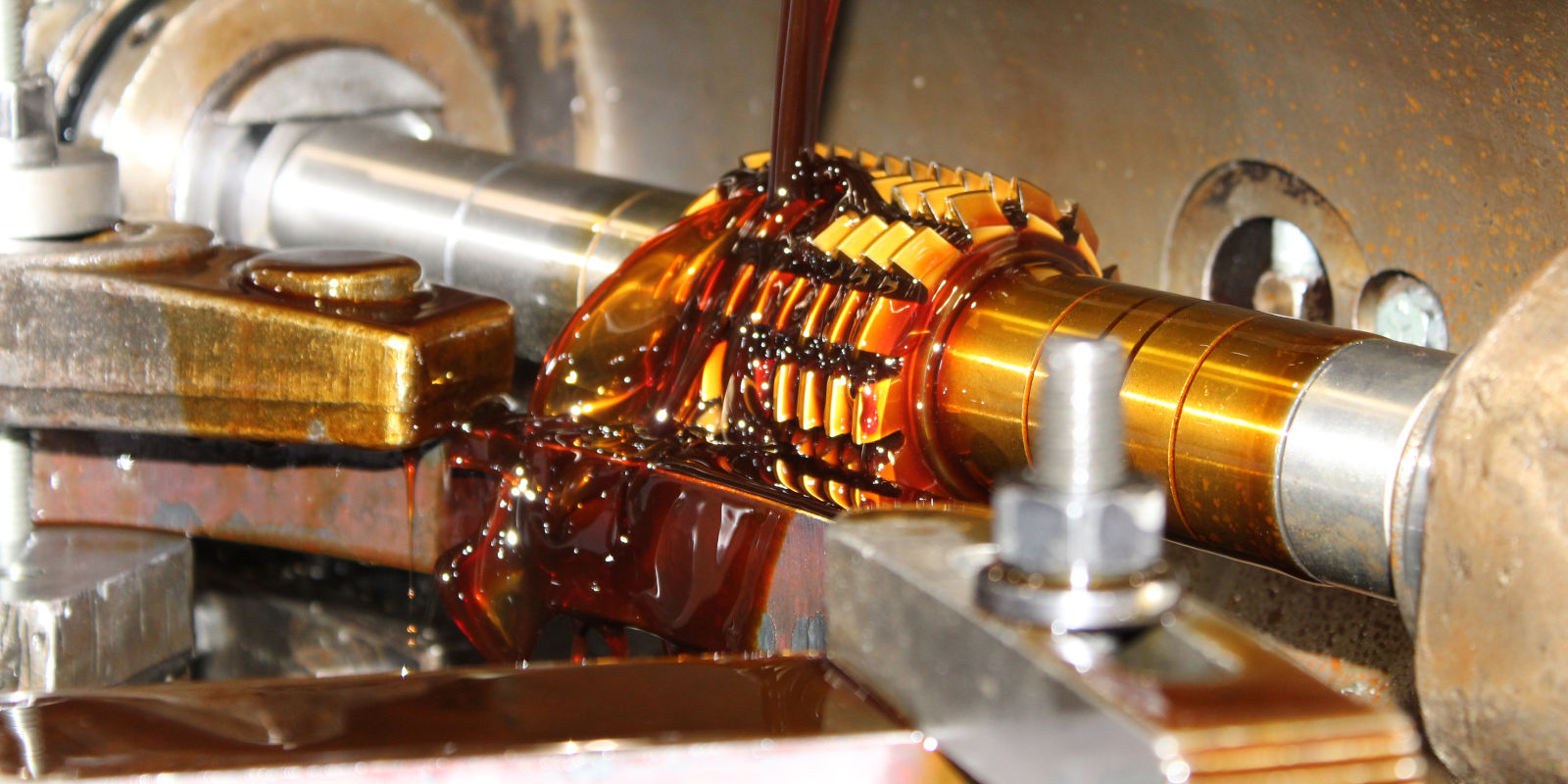

When manufacturers want gears to control a machine's speed, they'll pair together two gears with a different number of gear teeth.

When one gear has more teeth than the other gear, the smaller gear rotates faster to keep up with the larger gear. It's important to note that although the speed of the gear will increase, the force will remain the same. As these two gears operate together, the increased rotations will transmit power faster, and the machine's speed will increase.

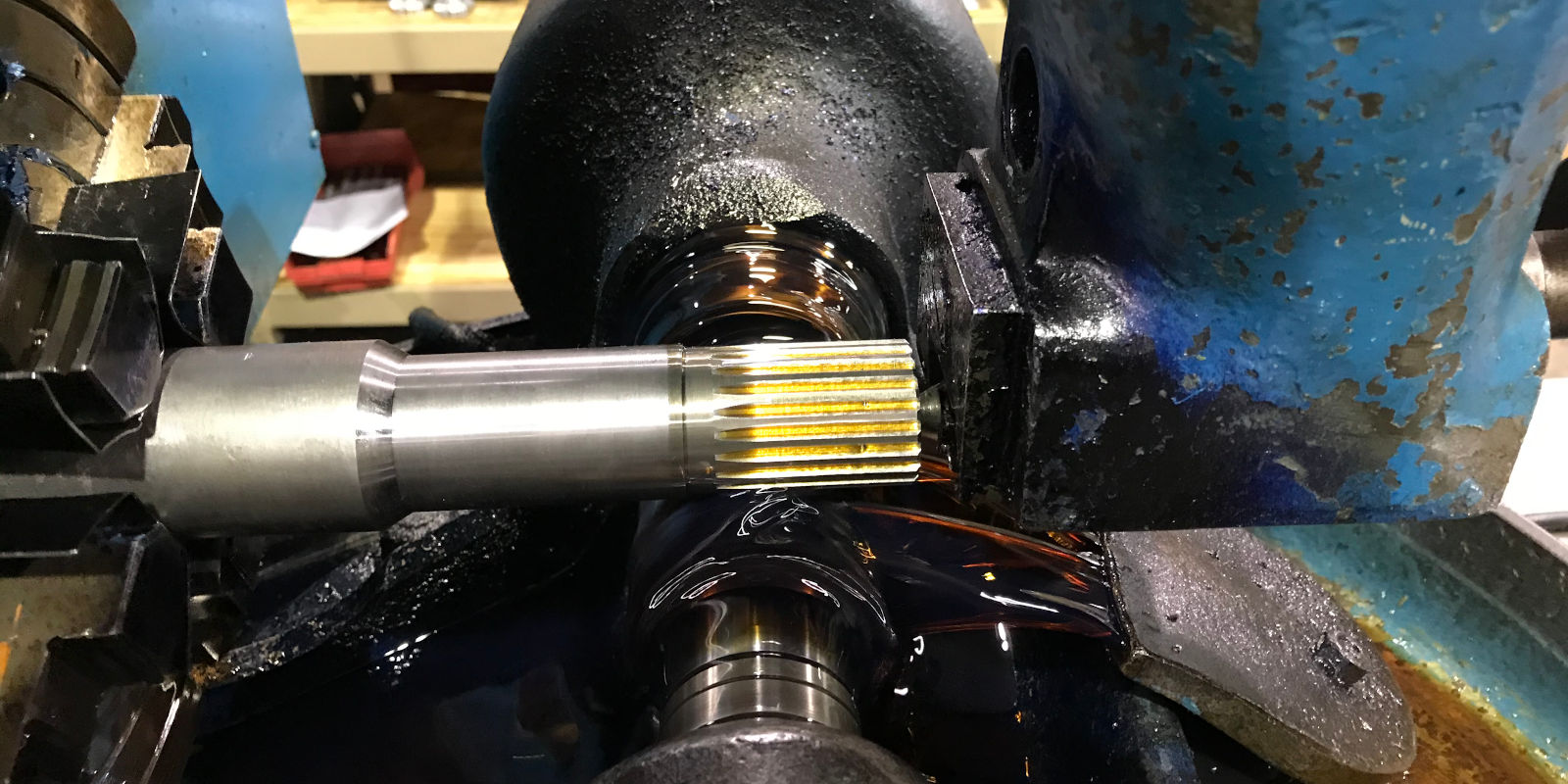

They Increase the Force

Similarly, if manufacturers want to control force, they can pair together two gears with a different number of gear teeth. However, to control the force, the first gear must have fewer teeth than the second gear. When the second gear has more teeth than the first gear, the cogs will turn more slowly, increasing force.

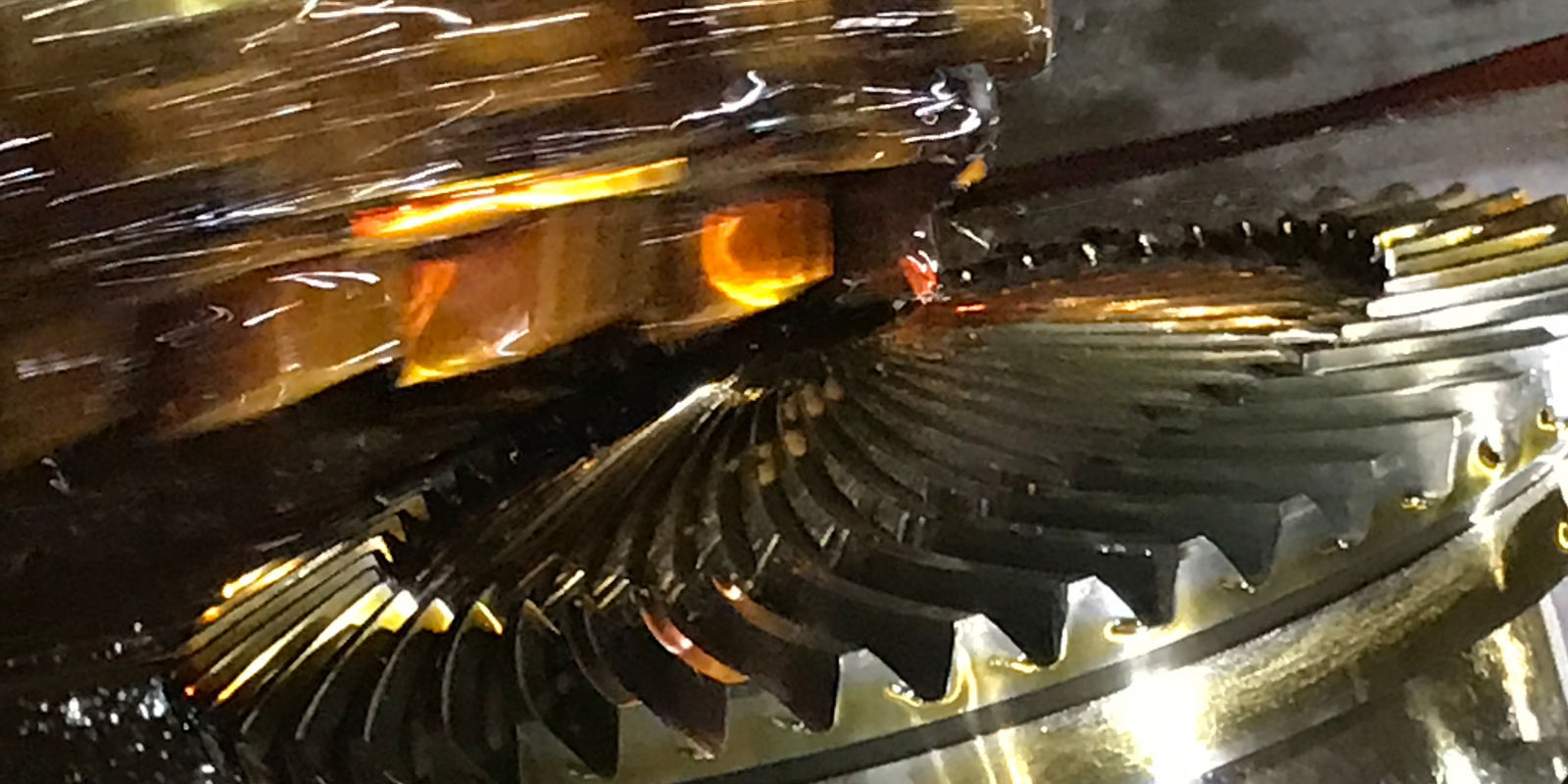

They Shift Direction

Gears are also commonly used to rotate directions inside machines and equipment. Manufacturers engineer gears so that when they intersect, they turn in opposite directions. When manufacturers design specified angles for gears, they can also create more precise controls when gears rotate against these angles.

Although understanding the science behind gears and how they work can be complicated, gears are essential to the functioning of machinery. Without these mechanisms, we could not control the speed, force, or direction of movement within our equipment and appliances.

Here at Hy-Tech's Power Transmission Group, we have extensive knowledge of gear types, gear applications, and custom gear manufacturing. Whether you need gearbox repairs or custom spur gears for your equipment, our team of experts can assist you with your mechanical needs.

For all other inquiries...

For all other inquiries...